Plasma Pyrolysis System

Features

- Waste to energy

- Low operational cost

- Stabilization of residue

- Low Carbon Footprint

- Minimized Ash Generation

- No generation of Dioxin & Furan

- Less time to Heat Waste

- Volumetric Weight Reduction

- Low Foot Print

- Emission Norms as per USEPA & MoEF Norms

Plasma Pyrolysis System

Request a Call Back

- Ask a Question

Plasma Pyrolysis System

Ask a Question

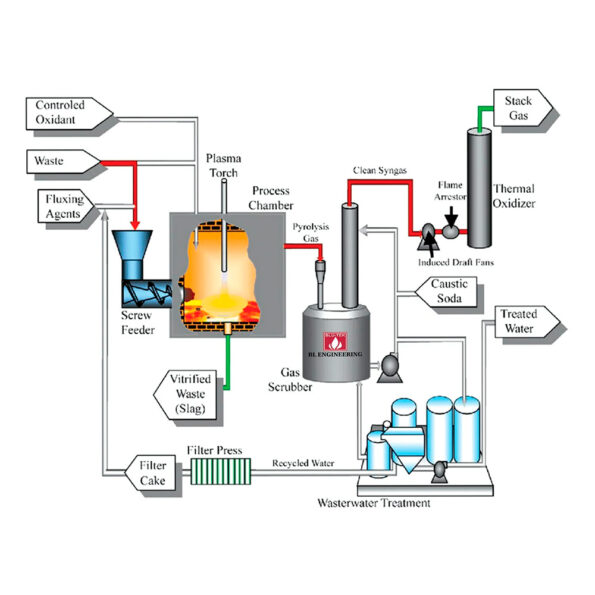

The pyrolysis process is a thermal disintegration of organic material into lower hydrocarbons particularly in the absence of oxygen. It results in the formation of combustible gases, organic liquid, char, and tar in varying quantities depending upon the feed composition, heating rate, temperature of pyrolysis, and residence time. The amount of char and tar formation reduces as the pyrolysis temperature increases. The temperature of the plasma zone is approx. 10,000°C and the surrounding temperature is 600°C–1200°C.

In plasma pyrolysis, the most likely compounds which are produced include carbonaceous matter, methane, carbon monoxide, hydrogen, carbon dioxide, and water molecules. These product gases are combustible. The exhaust gases generated on combusting the product gases include CO, N, H O. 2 2 2

The product gases recovered has calorific and commercial values. These gases can be used as a heat source or as fuel. The amount of gas recovered depends solely upon the type of waste and the amount of waste. As the system can recover energy from the waste while safely disposing of it, plasma pyrolysis can be treated as the ultimate waste management and recycling technology.

LITERATURE ABOUT PLASMA PYROLYSIS SYSTEM

Related Products

New product CovDecon food grade friendly UV with Plasma technology COVID19 disinfectant station developed by IIT Delhi and SMS HYDROTECH.

100% effective on multiple viruses Approved by Government Biotech Institute

BLUTEK designs and manufactures liquid waste combustion systems for a broad range of industrial, chemical, and pharmaceutical hazardous waste applications. We will design your system in either a horizontal or vertical down-fired configuration to meet your unique needs to control your environment. Each liquid waste combustion system is delivered complete, including a combustion system, liquid waste feed system, air pollution control device and controls.

Features:

- Horticulture/Agriculture Waste Shredder (Single Shaft)

- Plastic Waste Shredder(Single Shaft & Twin Shaft)

- Food Waste Shredder(Twin Shaft)

- Tire Waste Shredder (Twin Shaft)

- Bio Medical Waste (Single Shaft & Twin Shaft)

Horticulture Waste Recycling Machine coverts all agriculture/ horticulture waste into Biofuel Pellets.

Features:

- In Built Shredder and Conveyor Mixer

- Maintenance free

- Flawless operations

- Optimum performance

We are offering Solid Waste Compost Plant with following features.:

- Inbuilt Shredder

- Fully automatic machine with Siemens automation

- No discharge and no emission of harmful gases. .

- 100% natural 24 hours composting process

- Compact in size.

- High quality Organic Compost ready to use in 24 hours

- S.S 304 Machine Fabrication

- Decentralized solution for organic food waste management

- Noiseless, Odorless, Maintenance-free.

- No enzymes used.

- Reduces large amounts spent on transportation to landfill sites

- In-house waste management reducing dependence on any outside agency

Plastic Waste Recycling Machine converts all plastic waste into plastic granules.

Features:

- Good strength

- Cost-effective

- Low Maintenance

Sanitary Napkin Incinerator machines ensures environment friendly disposal of napkins anywhere. These small or mini sanitary incinerators are an suitable option for toilets of Schools and Colleges, Hostels and Hotels and public places like Shopping Malls, Railway Stations, Air Ports, Corporate and Government Offices, etc.

Thermal oxidation through incinerator is one of the proven technologies for destruction of solid waste of all types i.e. biomedical, pharmaceutical, radioactive, municipal, industrial, chemical and hazardous based on the feeding system, so as to render them innocuous in the form of non-toxic and non-hazardous residues.

BLUTEK TROMMEL is designed using centrifugal force and the jigging action of the drum rolling. In which different sizes of the materials can be screened. These materials or waste will be fed into their respective hoppers and separated by belt conveyors.

BLUTEK offers a wide range of capacities, custom-built as per the requirements of customers. Our robust design ensures trouble-free operation and a low-maintenance system.

Features:

- Ideal for bulk liquid disposal and incinerating contaminated solvent and aqueous liquid

- Operate with or without heat recovery

- Wet and dry scrubber air pollution control systems

- Can be combined with vent gas or fume streams for simultaneously processing liquid and gaseous waste streams

Features:

- Ideal for bulk liquid disposal and incinerating contaminated solvent and aqueous liquid

- Operate with or without heat recovery

- Wet and dry scrubber air pollution control systems

- Can be combined with vent gas or fume streams for simultaneously processing liquid and gaseous waste streams

We are offering Bio Mechanical Organic Waste Compost Machine with following features.

Key Features:

- Inbuilt Shredder

- Fully automatic machine with Siemens automation

- No discharge and no emission of harmful gases. .

- 100% natural 24 hours composting process

- Compact in size.

- High quality Organic Compost ready to use in 24 hours

- S.S 304 Machine Fabrication

- Decentralized solution for organic food waste management

- Noiseless, Odorless, Maintenance-free.

- No enzymes used.

- Reduces large amounts spent on transportation to landfill sites

- In-house waste management reducing dependence on any outside agency